3 phased motor – monitoring relay as motor guard

The RPN series monitoring relays offered by Relpol are excellent elements protecting the motor against failure, with which we can reliably monitor the current, voltage and temperature of the motor.

Process automation requires the use of more and more electric motors. Currently, they are used in every area of life: in production systems, transport, air conditioning and ventilation systems, and more and more often in buildings.

An electric motor is an electric machine that converts electrical energy into mechanical energy, in which the rotor rotates while skidding in relation to the rotating magnetic field created by the stator winding. The interaction of the rotating magnetic fields from the stator to the rotor creates an electromagnetic moment on the rotor, which causes the rotor to move.

Due to the high consumption of electricity, many industrial applications require advanced control and high reliability of electric motors. This is very important in processes where an unplanned stop of the drive will stop other strategically important equipment, resulting in high repair or downtime costs.

Statistics say that, most often, the motor becomes damaged in the event of:

- overload (30% of damages)

- loss of phase and power unbalance (14% of damages)

Motor operating overloads occur when the motor is too heavily loaded. The basic parameters that indicate motor overload are: too high current consumption, insufficient torque or overheating. Excess heat is the main cause of failure which leads to wear of the electrical and mechanical components of the motor, and thus leads to its permanent damage. For this reason, it is very important that we check that our motor is not overloaded during operation.

For 3-phase motors, the unbalanced current load is a big risk. The reason for this state is usually the asymmetry of supply voltages. The asymmetry of the three-phase power supply system consists in the appearance of differences between the effective value of the phase-to-phase voltages and the angular shift of these voltages. In standard motor operation, each voltage is shifted by 120 degrees, in such conditions the vectors of these three voltages are equal and form an equilateral triangle or a star, depending on the motor connection. Imbalance causes too much current to flow in one or more phases, increasing the operating temperature and damaging the motor insulation, resulting in motor immobilization and unplanned machine downtime.

Electric motor control systems are widely used in industrial plants for very important production processes. Equipment failure can result in major damage and financial loss, both due to the cost of replacing or repairing motors as well as the cost of line downtime. Some breakdowns can be avoided if we manage to provide maintenance services with information about improper motor operation before their damage or even stop the motor in an unfavorable situation.

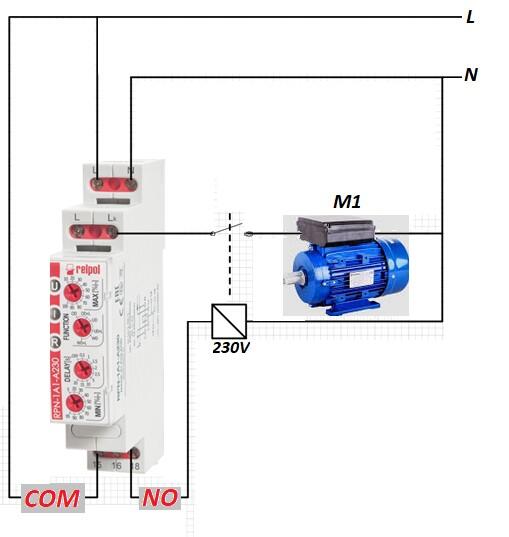

In order to protect the 1-phase motor and other devices against overloads, a reliable control element is the RPN-1A ..- A230 current control relay, which enables the supervision of the AC current in the 1-phase network in the range from 0.5 - 16A. This relay has 6 current monitoring functions.

We can control the supervision:

- maximum current value (OD - OVER D),

- maximum current value with error memory (OD + L - OVER D + LATCH),

- minimum current value (UD - UNDER D),

- minimum current value with error memory (UD + L - UNDER D + LATCH),

- maximum and minimum current values in the window function (WD - WIN D),

maximum and minimum current values in the window function with the error memory function (WD + L– WIN D + LATCH).

Using the above functions, it is possible to control both too high and too low current, with the possibility of its control in a given window. A very important element of the control system is the ability to select functions with error memory. Thanks to this, if required, the motor will not restart by itself without the consent of the operator, who must clear the error. In many cases, this can protect the health and even life of the operator.

Figure 1. An example of the RPN-1A16-A230 relay application to control the motor current.

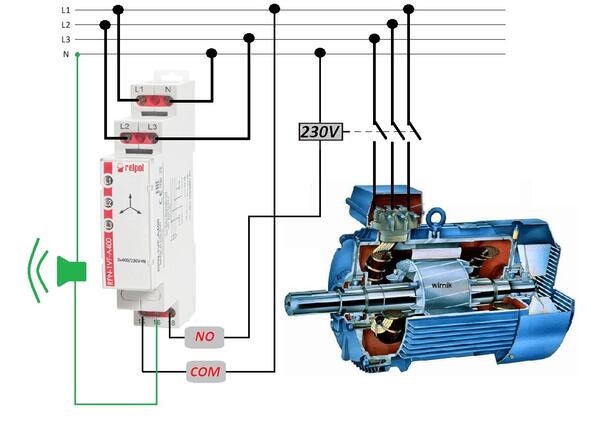

For systems where we want to control the power level, the best solution is to use the RPN-1VFT-A400 relay. With this relay we can monitor the loss and sequence of phases as well as asymmetry. The relay also gives us the ability to set both the asymmetry range from 0 to 80%, as well as the delay range up to 9s. The relay, using the LOST D function, controls the phase loss. After connecting the supply voltage, the relay will check if the voltage on all phases is above 175V, if so, the R operating relay will be activated, which will switch the motor on by controlling the contactor's coil. If the voltage on one of the 3 phases L1, L2, L3 drops to 175V, the relay after measuring the delay time of 4s (in the case of the RPN-1VFT-A400 relay, this time can be changed in the range from 0 to 9s, in 1s increments) ) will disconnect the R working contact, which will stop the motor and, additionally, by connecting the signaling device to the 1N / C contact, the alarm will be triggered. The relay will close the R working contact again if the voltage on a given phase increases to 180V. Additionally, the relay, using the ASYM D function, controls the asymmetry. In the case of asymmetry greater than 55V, the relay will also disconnect the motor after the same time as in the case of phase loss control.

Figure 2. An example of the RPN-1VF-A400 relay application to control phase failure and voltage unbalance.

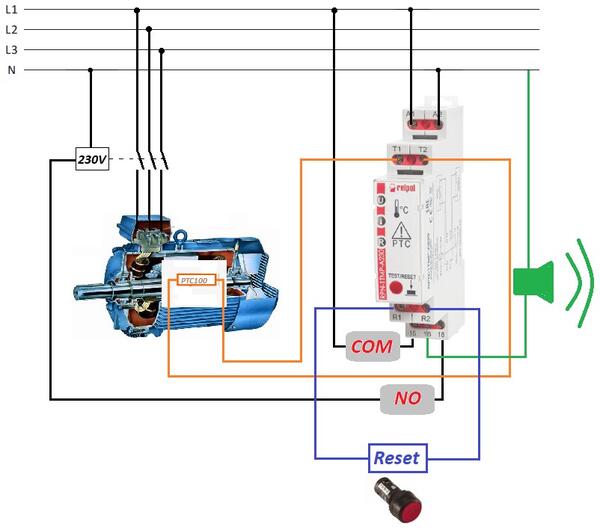

The last element of motor control is its temperature. Using the RPN-1TMP-A230 relay, we can connect up to 6 PT100 sensors to the motor windings. This makes it possible to control the motor winding with an error memory. With the supply voltage on and the resistance of PTC sensors lower than 3.6kΩ, the output relay R will switch on. The R output relay will be turned off, and thus the motor will stop working when the total resistance of the circuit exceeds 3.6kΩ (the temperature increases). The executive relay will be turned on again if the total resistance of the sensors drops below 1.65kΩ (the system is cooled down) and one of the following three conditions is met:

- the TEST / RESET button is pressed

- an external RESET button is pressed (connected between terminals R1 and R2),

- the supply voltage is switched off and on again.

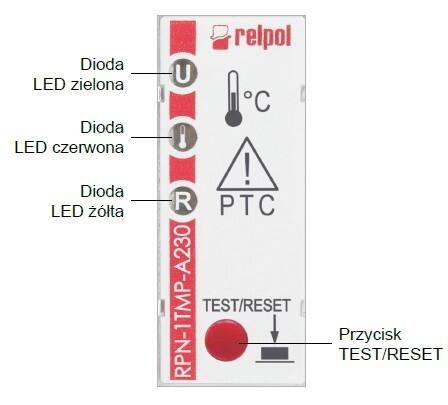

If the resistance of the sensors is in the range from 3.3 kΩ to 3.6 kΩ, the relay will enter the warning mode, which will be indicated by the flashing red LED on the front panel. If the red LED is lit continuously, it indicates motor failure and disconnection of the operating relay R, which is also visible in the form of no yellow LED.

During the correct operation of the motor, both the green LED diode is on, indicating that the relay is properly powered, and the yellow LED, indicating that the R relay is on.

Figure 3. RPN-1TMP-A230 relay front panel.

Also, in the case of a sensor short-circuit, when their resistance drops below 10Ω, the operating relay R will be disconnected, which will stop the motor.

Figure 4. Example of the RPN-1TMP-A230 relay application to control the motor temperature.

Summarizing the above, it can be seen that by using Relpol RPN series supervisory relays, one can easily control the operation of the motors to ensure their safe operation and eliminate the possibility of a sudden failure and stoppage of the production process.

It should also be remembered that there are many possibilities of using RPN series supervisory relays, manufactured by Relpol SA, which can be seen in the following examples:

- Motor energy consumption,

- Control of lighting and heating installations,

- Overload situations for winches and transport devices,

- Checking the immobilizing devices and limit switches,

- Control of ventilation devices,

- Power control of machines and devices,

- Protection against damage to receivers in unstable power networks,

- Control of the directions of rotation of motors,

- Protection of motors in 3-phase networks,

- Temperature control of motor windings,

- Protection of motors against thermal overload.